Unveiling the Economics of Zinc Pyrithione Production: A Cost Analysis Report

Zinc pyrithione, a broad-spectrum antimicrobial agent, finds widespread use in various applications, including personal care, household products, and industrial preservatives. With the recent Zinc Pyrithione Production Cost Analysis Report, procurement professionals and industry experts can explore the comprehensive processes involved in manufacturing this chemical and gain deeper insights into its cost structure.

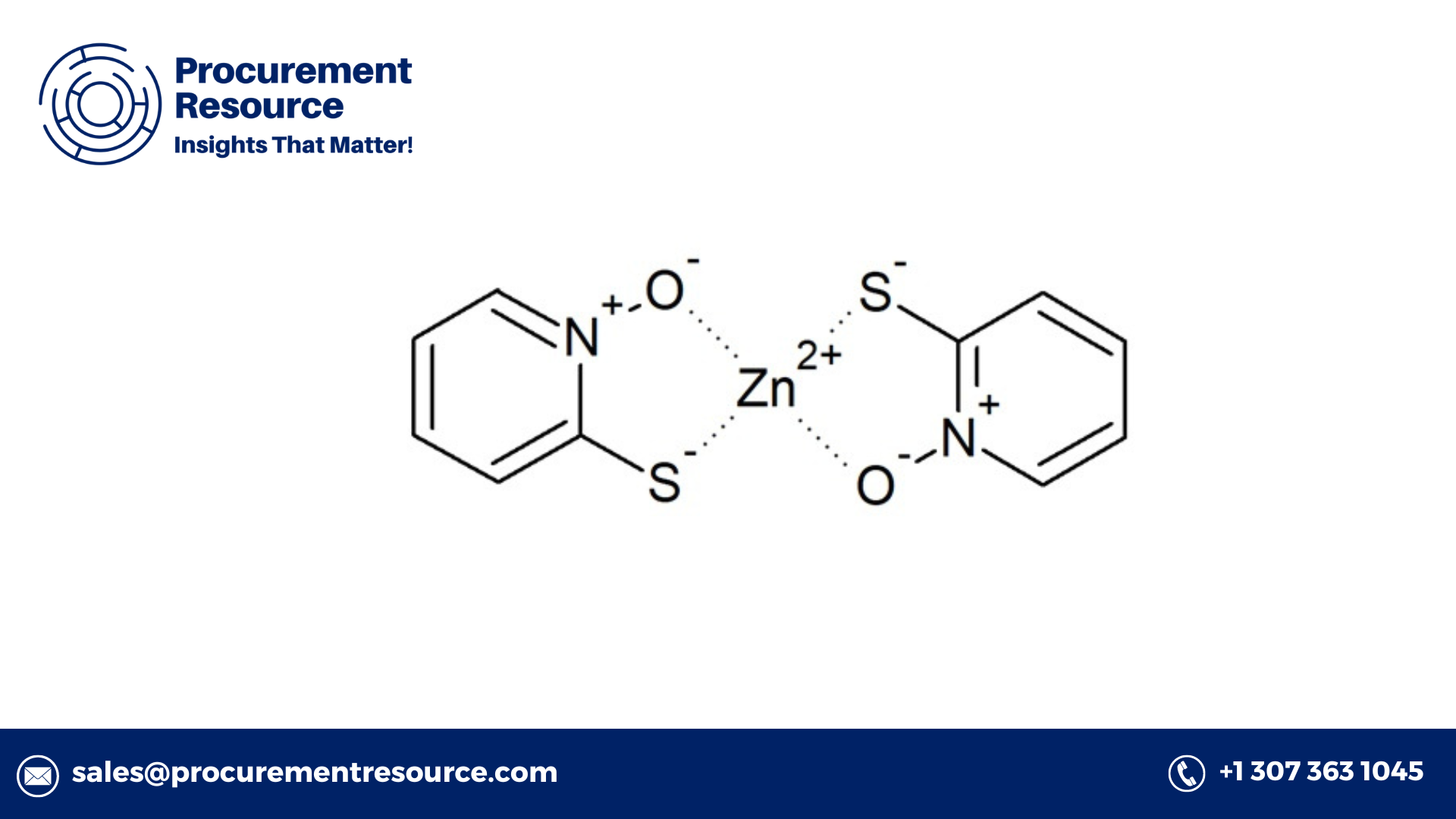

Definition of Zinc Pyrithione

Zinc pyrithione, also known as ZPT, is a chemical compound known for its antifungal and antibacterial properties. It appears as a white powder and is only sparingly soluble in water but readily dissolves in ethanol and other solvents. Since its development in the 1930s, zinc pyrithione has served various industries as an essential preservative and antimicrobial agent. It’s particularly popular in personal care items like anti-dandruff shampoos and skincare products, where its effectiveness against dandruff and seborrheic dermatitis has proven crucial.

Request For Sample: https://www.procurementresource.com/production-cost-report-store/zinc-pyrithione/request-sample

Procurement Resource Assessment of Zinc Pyrithione Production Process

The production process of zinc pyrithione requires careful management due to its multifaceted chemical reactions and raw material requirements. Procurement Resource has meticulously analyzed the different stages of production:

- Raw Material Procurement: The primary components include zinc salts and pyrithione ligands. Securing high-quality and cost-efficient raw materials is critical, and suppliers must ensure consistency in supply.

- Chemical Synthesis: The synthesis process generally involves the reaction between zinc salts (like zinc sulfate or zinc oxide) and pyrithione ligands. This requires specialized equipment and technical expertise to yield high-purity zinc pyrithione efficiently.

- Purification and Packaging: After synthesis, the compound undergoes purification to remove impurities. The final product is then packaged in suitable containers, ensuring product safety and integrity throughout its supply chain.

The analysis thoroughly evaluates the costs associated with each stage, from raw material procurement to the final product. This comprehensive overview helps procurement teams and manufacturers identify critical cost-saving opportunities and streamline their supply chain strategies.

Market Drivers of Zinc Pyrithione

The global zinc pyrithione market is driven by several key factors, including:

- Growing Demand in Personal Care: The rising consumer focus on personal hygiene, particularly post-pandemic, has spurred the demand for effective antimicrobial agents. Zinc pyrithione’s proven efficacy against dandruff and other scalp conditions has made it a staple ingredient in anti-dandruff shampoos.

- Industrial Applications: Beyond personal care, zinc pyrithione’s antifungal and antibacterial properties make it useful as a preservative in paints, coatings, and other industrial products. It prevents mold and algae growth, extending the lifespan of coated surfaces.

- Stringent Regulations: Many countries have enacted stringent regulations on harmful preservatives in consumer products, opening up opportunities for safer alternatives like zinc pyrithione.

- R&D Investments: Continuous research and development in improving zinc pyrithione formulations enhance its application scope and efficiency. Innovations like microencapsulation help extend its shelf life and reduce environmental impacts.

Latest News for the Zinc Pyrithione Market

The zinc pyrithione market continues to evolve with changing consumer preferences and regulatory landscapes:

- Formulation Innovations: Manufacturers have developed more stable and environmentally friendly zinc pyrithione formulations for personal care and industrial applications.

- Sustainability Initiatives: Companies are striving to produce zinc pyrithione through greener, more sustainable processes that minimize waste and energy consumption.

- Market Consolidation: Industry players are increasingly seeking mergers and acquisitions to strengthen their market presence and expand their global distribution networks.

- Regulatory Changes: Regulatory authorities in regions like Europe have reviewed zinc pyrithione’s usage limits, resulting in manufacturers exploring novel, safe formulations.

Product Details of Zinc Pyrithione

Zinc pyrithione is available in several grades and forms:

- Technical Grade: Primarily used in industrial applications like paint and coating preservatives.

- Cosmetic Grade: Specially formulated for personal care applications, including anti-dandruff shampoos, skincare creams, and body lotions.

- Form Factors: It is typically available as a powder or a dispersion, suitable for various application needs.

Key Questions Answered in This Report

- What is the comprehensive production cost analysis for zinc pyrithione, and what are the primary cost drivers?

- How do variations in raw material prices affect the overall production cost structure?

- What are the critical challenges in the procurement of raw materials, and how can they be mitigated?

- How does the regulatory landscape impact the production and distribution of zinc pyrithione?

- What market trends will shape the future demand and supply of zinc pyrithione?

- What cost optimization strategies can procurement teams adopt to streamline the production process?

Looking for an Exhaustive and Personalized Report That Could Significantly Substantiate Your Business?

The zinc pyrithione production cost analysis report is a valuable resource for stakeholders seeking detailed insights into the production processes and market dynamics of this critical compound. By offering a comprehensive assessment of costs, procurement strategies, and market trends, this report empowers businesses to make informed decisions.

- Personalized Recommendations: Customizable insights and recommendations tailored to your business model, target markets, and growth objectives.

- Comprehensive Analysis: An exhaustive cost analysis covering everything from raw materials to distribution strategies.

- Market Forecasts: In-depth market forecasts to help your team stay ahead of industry trends and challenges.

- Supply Chain Optimization: Strategies for optimizing procurement and supply chains to minimize costs and enhance competitiveness.

Conclusion

The Zinc Pyrithione Production Cost Analysis Report by Procurement Resource provides a comprehensive examination of zinc pyrithione’s production processes and cost structure. Understanding these aspects can help manufacturers and procurement professionals optimize their supply chain, reduce production costs, and maximize market opportunities. As the demand for zinc pyrithione continues to grow across personal care and industrial applications, this detailed analysis provides crucial insights for stakeholders looking to strengthen their strategic positioning and operational efficiency.