Leveraging Video Analytics for the Manufacturing Industry

In recent years, artificial intelligence (AI) has revolutionized various industries, including manufacturing. One of the most transformative applications of AI in this sector is video analytics. By harnessing AI-driven video analytics, manufacturers can significantly enhance their operational efficiency, improve safety, ensure quality, and reduce costs. This comprehensive exploration delves into how AI video analytics is leveraged in the manufacturing industry and its myriad benefits.

Enhancing Operational Efficiency

Operational efficiency is paramount in manufacturing, where even minor inefficiencies can lead to significant losses. AI video analytics can optimize various aspects of manufacturing operations:

- Process Optimization: AI video analytics can monitor production lines in real-time, identifying bottlenecks and inefficiencies. By analyzing video feeds, AI systems can detect anomalies such as slow-moving conveyor belts or improperly functioning machinery, allowing for immediate corrective actions.

- Predictive Maintenance: AI-powered video analytics can monitor the condition of equipment continuously. By analyzing visual data, AI can predict potential failures before they occur, scheduling maintenance proactively. This predictive maintenance reduces downtime and extends the lifespan of machinery.

- Inventory Management: Video analytics can assist in monitoring inventory levels in real-time. AI systems can track the movement of goods within the facility, ensuring optimal stock levels are maintained and reducing the risk of overstocking or stockouts.

Improving Safety

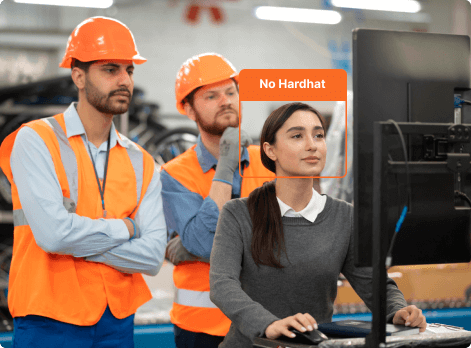

Safety is a critical concern in manufacturing due to the high-risk environment. AI video analytics can significantly enhance workplace safety:

- Hazard Detection: AI systems can detect potential hazards such as spills, obstructions, or unsafe worker behavior. For instance, video analytics can identify when workers are not wearing required safety gear and alert supervisors in real-time.

- Accident Prevention: By continuously monitoring the work environment, AI can identify patterns that may lead to accidents. For example, it can recognize when machinery is being operated unsafely or when workers are too close to dangerous equipment.

- Emergency Response: In case of an emergency, AI video analytics can facilitate quick and effective response. For example, it can detect fires or chemical leaks and automatically trigger alarms, initiate shutdown procedures, and guide emergency responders to the affected area.

Ensuring Quality Control

Maintaining high-quality standards is crucial for manufacturing. AI video analytics plays a vital role in quality control:

- Defect Detection: AI systems can analyze video feeds from production lines to detect defects in real-time. This includes identifying surface imperfections, incorrect assembly, or faulty components, ensuring that only high-quality products reach the market.

- Process Compliance: AI can monitor manufacturing processes to ensure compliance with predefined standards and protocols. By analyzing video data, AI systems can verify that each step of the production process is performed correctly, reducing the likelihood of errors.

- Traceability: Video analytics can provide detailed records of the manufacturing process, offering traceability for each product. This is particularly important for industries with strict regulatory requirements, such as pharmaceuticals and food production.

Reducing Costs

Cost reduction is a primary goal for manufacturers, and AI video analytics contributes significantly to this objective:

- Labor Efficiency: By automating the monitoring and analysis of video feeds, AI reduces the need for human oversight. This allows skilled workers to focus on more strategic tasks, increasing overall labor efficiency.

- Waste Reduction: AI can identify inefficiencies and defects early in the production process, minimizing waste. For example, by detecting defective raw materials or components before they are used, manufacturers can prevent costly rework and material wastage.

- Energy Management: AI video analytics can monitor energy usage across the facility. By analyzing patterns in video data, AI systems can identify opportunities for energy savings, such as optimizing the operation of machinery and lighting.

Real-World Applications

Several real-world applications highlight the effectiveness of AI video analytics in manufacturing:

- Automotive Industry: In automotive manufacturing, AI video analytics is used to inspect parts and assemblies for defects, ensuring high quality. It also monitors the assembly line for any irregularities that could lead to defects.

- Electronics Manufacturing: AI systems inspect printed circuit boards (PCBs) and other electronic components for defects, ensuring that only functional and high-quality products are shipped.

- Food and Beverage: AI video analytics monitors the production process to ensure compliance with hygiene standards and detect any contamination. It also inspects packaging for defects and ensures proper labeling.

- Pharmaceuticals: In pharmaceutical manufacturing, video analytics ensures that production processes comply with stringent regulatory requirements. It monitors the filling, sealing, and packaging processes to ensure product safety and quality.

Challenges and Future Directions

While the benefits of AI video analytics in manufacturing are substantial, several challenges must be addressed:

- Data Privacy and Security: The use of video analytics involves collecting and analyzing large amounts of visual data, raising concerns about data privacy and security. Manufacturers must implement robust security measures to protect sensitive information.

- Integration with Existing Systems: Integrating video analytics with existing manufacturing systems can be complex. It requires seamless integration with other industrial IoT devices, enterprise resource planning (ERP) systems, and manufacturing execution systems (MES).

- Cost of Implementation: The initial cost of implementing video analytics can be high, including costs for hardware, software, and skilled personnel. However, the long-term benefits often justify the investment.

- Skill Gap: Implementing and maintaining video analytics systems require specialized skills. Manufacturers need to invest in training and development to bridge the skill gap.

Despite these challenges, the future of video analytics in manufacturing looks promising. Advances in AI algorithms, increased computational power, and the proliferation of IoT devices will further enhance the capabilities of video analytics. Future developments may include more sophisticated anomaly detection, enhanced predictive maintenance capabilities, and greater integration with other AI-driven industrial solutions.

Conclusion

AI video analytics software is transforming the manufacturing industry by enhancing operational efficiency, improving safety, ensuring quality, and reducing costs. By leveraging advanced AI technologies, manufacturers can gain real-time insights, automate critical processes, and make data-driven decisions. As the technology continues to evolve, video analytics will become an indispensable tool for manufacturers seeking to stay competitive in a rapidly changing landscape. Embracing this technology today will pave the way for smarter, safer, and more efficient manufacturing operations in the future.