Knowing the MES Manufacturing Execution System: The Foundation of Industrial Production

Businesses are always looking for methods to increase productivity, cut expenses, and uphold high standards of quality in the fast-paced, cutthroat manufacturing world of today. The Manufacturing Execution System, or MES, is one of the most important technologies that have surfaced in recent years. A vital component of contemporary manufacturing, the MES system serves as a link between shop floor operations and enterprise-level planning.

The importance of the MES software, its function as the foundation of the manufacturing information system, and its role in optimizing production processes will all be covered in this article.

The importance of the MES software, its function as the foundation of the manufacturing information system, and its role in optimizing production processes will all be covered in this article.

MES Manufacturing Execution System: What is it?

A digital tool called a Manufacturing Execution System (MES) keeps tabs on, records, and controls the factory floor production process. It helps manufacturers streamline processes, reduce downtime, and guarantee product quality by giving them real-time visibility into production activity. MES systems assist in coordinating production activities with overarching company objectives by connecting with enterprise resource planning (ERP) systems.

Businesses may monitor and trace materials, work-in-progress, and completed goods during the whole manufacturing process with the help of the MES system. It gathers vital information about inventory levels, worker productivity, and machine performance, offering important insights for ongoing development.

Essential Elements of MES Software

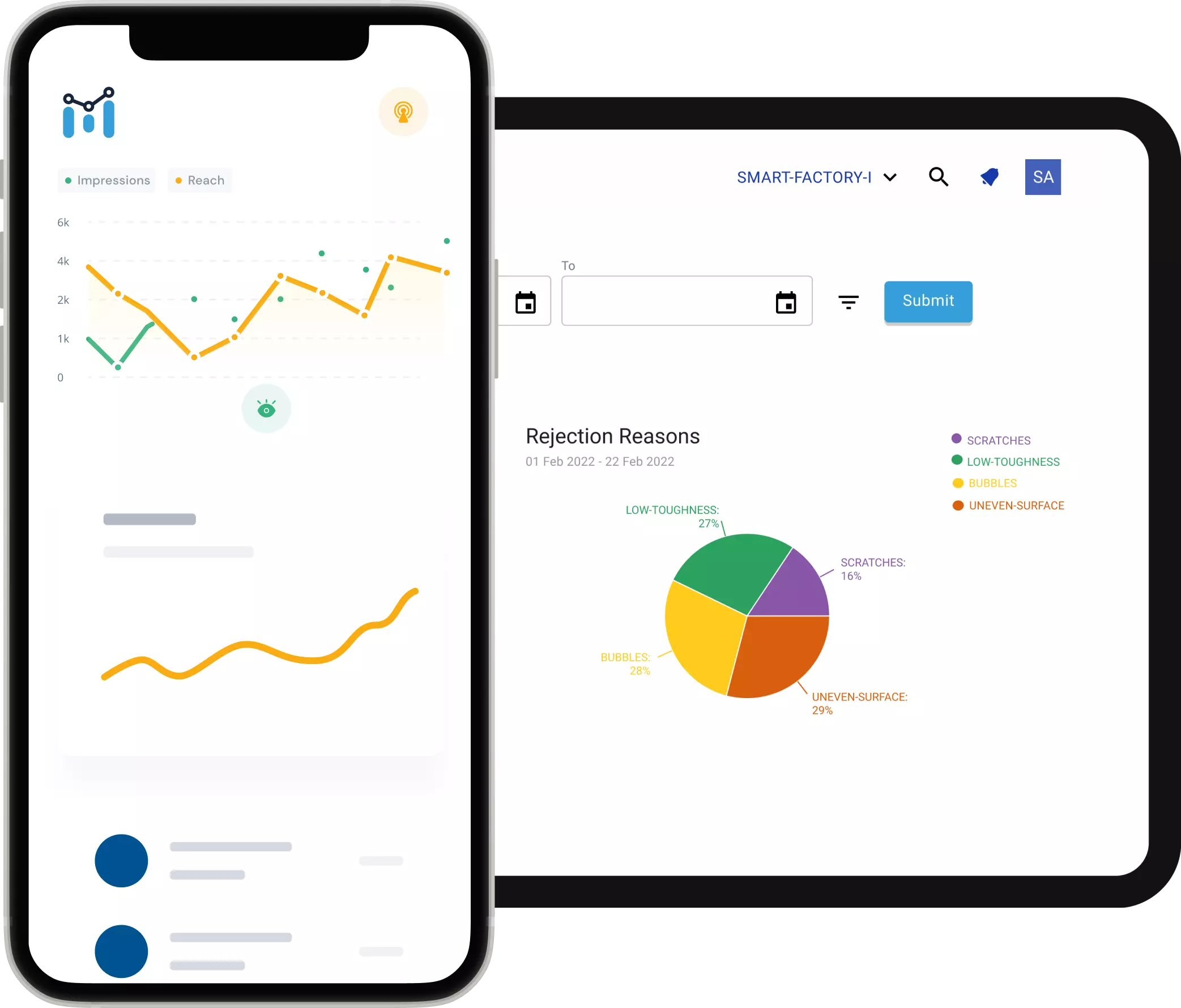

Inspection and Control in Real Time

The capacity of MES software to offer real-time manufacturing operation monitoring is among its most important benefits. The technology guarantees that managers have a thorough understanding of production in real-time by gathering data from machines, sensors, and operators. This enables them to promptly detect problems or bottlenecks and take remedial action before they worsen.

Making Decisions Based on Data

Large volumes of data are gathered by MES systems, and these data can be examined to get understanding of how well processes are doing. Manufacturers are empowered to optimize production schedules, make well-informed decisions, and increase overall efficiency with this data-driven strategy. Driving continuous improvement requires the ability to monitor and evaluate key performance indicators (KPIs), such as cycle times, yield, and scrap rates.

Improved Traceability

Manufacturers can monitor each product or batch as it progresses through the manufacturing process with the help of the MES system. This improved traceability guarantees adherence to quality standards and industry requirements. The MES software lowers the risks to brand reputation and safety by making it simpler to identify and locate impacted products in the event of a product recall.

Management of Inventory

Smooth operations depend on efficient inventory management. Accurate, up-to-date information on raw materials, work-in-progress products, and completed commodities is provided by MES software. Manufacturers can eliminate expensive stockouts or overproduction, cut waste, and improve stock level management by integrating this data with an ERP system.

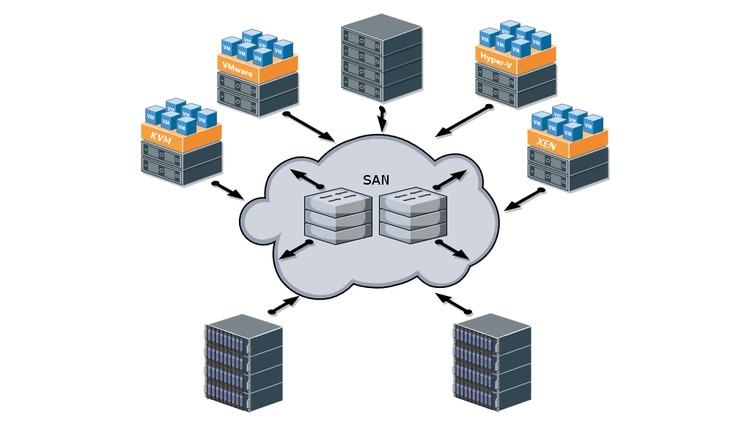

The Integration of Manufacturing Information Systems with MES Systems

In the larger production information system, a MES system is essential. It acts as the center for communication between different company systems, production equipment, and gadgets. Supply chain management software and ERP are examples of higher-level systems that MES connects the shop floor with to make sure manufacturing processes are in line with the overarching business plan.

For instance, the MES software can automatically modify production plans to satisfy demand when an order is placed via the ERP system. Better departmental collaboration is made possible by the MES system’s ability to deliver updates on each order’s status as production moves forward. Errors are decreased, productivity is increased, and production operations are carried out effectively thanks to this smooth integration.

Advantages of MES System Implementation

Improved Productivity

MES software assists firms in optimizing production flows by automating critical processes and offering real-time visibility. Operational efficiency increases when downtime is decreased, manual processes are eliminated, and team coordination is enhanced.

Enhanced Quality of the Product

More control over production parameters is possible with MES systems, guaranteeing constant product quality. Manufacturers can detect and fix problems before they have an impact on the finished product by keeping an eye on operator behavior and machine performance in real time.

Cutting Expenses

Implementing a MES system can drastically reduce costs by improving labor efficiency, inventory management, and waste reduction. The data analytics features of the program also assist in locating areas where quality may be maintained while costs can be reduced.

In conclusion

For firms trying to stay ahead in a sector that is changing quickly, the MES Manufacturing Execution System is revolutionary. The MES system is a vital component of contemporary production since it offers real-time insights, boosts productivity, and guarantees higher-quality products. MES software can give you a competitive edge and help you streamline operations, whether your goals are cost reduction, production process optimization, or regulatory compliance.

MES software guarantees that every element of the manufacturing process functions in unison as part of a larger manufacturing information system, allowing companies to accomplish their objectives more successfully and economically.