Artificial Intelligence (AI) has become a game-changer across industries, offering a range of benefits from automation to enhancing decision-making. Within the AI landscape, computer vision stands out as a powerful tool that is increasingly transforming various sectors, including pharmaceuticals. The integration of computer vision in pharmaceutical manufacturing is not just a technological upgrade but a significant leap forward in digitizing processes, improving efficiency, and enhancing product quality. This article will delve into the key applications of computer vision in the pharmaceutical industry, highlighting how this innovative technology is reshaping the way pharmaceutical companies operate.

The Role of Computer Vision in Pharmaceuticals

Computer vision, which involves using AI to analyze and interpret visual data, is playing a key role in automating tasks that were previously performed manually. This technology is particularly beneficial in industries like pharmaceuticals, where quality control and regulatory compliance are critical. By using camera sensors for object detection and image recognition, computer vision provides a minimal operational footprint while gathering vast amounts of information that would be otherwise difficult to track manually.

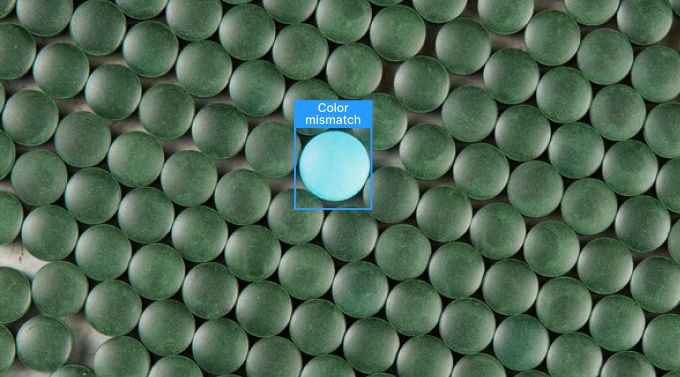

In pharmaceutical manufacturing, computer vision is most commonly used to detect defects, improve quality control, and streamline the overall production process. With the integration of deep learning and edge computing technologies, it is now possible to detect defects in real-time, leading to faster feedback and cost reductions. AI-powered visual systems use images and video streams from cameras to identify anomalies, deviations, and faults in production, helping companies avoid costly mistakes and maintain high-quality standards.

Quality Control and Capsule Inspection

A major concern in pharmaceutical manufacturing is the need for stringent quality control at every step of production. The quality of capsules, for example, needs to be verified for size, shape, color, and other characteristics to ensure that they meet the required standards. Manual inspection of these capsules is time-consuming and error-prone, which can lead to delays and inconsistency in production.

By implementing computer vision technology for real-time inspection of gelatin capsules, manufacturers can automate this critical task. Advanced imaging software analyzes digital video or image data to detect defects such as dents, holes, double caps, dirt, and color inconsistencies. This automation not only speeds up the process but also enhances the accuracy and consistency of quality control efforts.

Deep learning techniques are also employed to enhance the effectiveness of the inspection system. By training machine learning models on large datasets, these systems can learn to recognize subtle defects and improve over time. Additionally, predictive maintenance algorithms ensure that the machinery involved in production is operating optimally, preventing unexpected failures and ensuring continuous production.

Automating Visual Inspections

Another area where computer vision is revolutionizing pharmaceutical manufacturing is in the automation of visual inspections. For instance, in blister packaging, it’s crucial to detect any missing or broken tablets. Manual checks can be slow and inconsistent, leading to missed errors or delays in production.

Computer vision systems that leverage machine learning algorithms can detect even the smallest anomalies in blister packaging, such as changes in tablet color, size, or shape. These systems can instantly flag defective packages, allowing for quick corrective actions. The ability to automatically inspect and detect defects in real-time ensures that the pharmaceutical company maintains high standards of product quality and regulatory compliance.

Tracking Employee Movements for Increased Productivity

Employee monitoring and productivity tracking is another application of computer vision in pharmaceutical manufacturing. By using AI-powered cameras and monitoring systems, it’s possible to ensure that employees are working efficiently and focusing on their tasks. With real-time surveillance, manufacturers can track the movements of employees within the premises, reducing the risk of distractions or non-productive behavior.

This level of monitoring enhances productivity by ensuring that workers remain focused on their duties, ultimately improving the efficiency of the entire production process. Furthermore, such monitoring systems can help with safety compliance, ensuring that employees follow all required protocols and procedures within the workplace.

Lot Code and Label Verification

Pharmaceutical packaging is often equipped with essential information, including lot codes, expiration dates, and product labels. Ensuring that this data is correctly printed and visible on each package is critical for regulatory compliance and patient safety. Manual checks for verifying this information can be slow and prone to errors.

With the help of Optical Character Recognition (OCR) and Optical Character Verification (OCV), computer vision systems can automatically verify the printed information on each package. OCR reads the text, while OCV ensures that the printed data matches the required specifications. This automated verification process eliminates the risk of human error and ensures that the pharmaceutical company meets regulatory standards for labeling and packaging.

Precision in Vial Inspection

In the pharmaceutical industry, producing large quantities of vials of liquid medicine comes with the challenge of maintaining high-quality standards while ensuring safety. Vials can be prone to issues like cross-contamination, defects, or contamination by foreign substances. Detecting such issues early is crucial to maintaining the safety of consumers.

Computer vision systems are equipped to monitor and inspect vials in real time for defects and contamination. With deep learning algorithms that are trained to identify complex patterns in large datasets, these systems can detect contaminants or defects with exceptional accuracy. This improves product quality and helps pharmaceutical companies reduce the risks associated with faulty products reaching the market.

Deep Learning and Edge Computing in Pharmaceuticals

The integration of deep learning and edge computing is crucial in optimizing the performance of computer vision systems in the pharmaceutical sector. Deep learning models are trained on large datasets, which enable them to recognize intricate patterns and detect even the most subtle defects. When deployed at the edge, these systems can process data locally without needing to rely on cloud infrastructure, enabling faster decision-making and real-time analysis.

By leveraging these technologies, pharmaceutical companies can achieve remarkable accuracy in defect detection and anomaly recognition. The ability to analyze large volumes of data quickly and accurately improves the overall efficiency of production processes and helps pharmaceutical companies stay ahead of the competition.

Automation and Robotics Boost Efficiency

AI-powered robotics play a crucial role in automating various tasks within the pharmaceutical industry. These robots can be used to detect defects in real time and remove defective products from the production line with precision. Equipped with vision AI systems, robotic arms can perform intricate tasks with minimal human intervention, reducing the risk of errors and improving the overall speed of the manufacturing process.

By integrating computer vision with robotics, pharmaceutical companies can achieve higher levels of automation, reducing the need for human labor and lowering operational costs. This results in more efficient production processes, improved product quality, and faster time-to-market for pharmaceutical products.

Final Thoughts

Traditionally, pharmaceutical manufacturing relied on manual and semi-automated quality control processes. However, these methods were subject to human error and inconsistencies, which often led to defects and costly mistakes. With the advent of computer vision and deep learning technologies, pharmaceutical companies can now automate critical tasks, improve quality control, and enhance production efficiency.

At Nextbrain, we help pharmaceutical companies leverage AI video analytics software to enhance their operations. Our platform offers an integrated set of tools that support the full application lifecycle, from image annotation to deploying machine learning models. By embracing computer vision and AI technologies, pharmaceutical companies can enhance their productivity, ensure compliance, and produce higher-quality products for consumers.