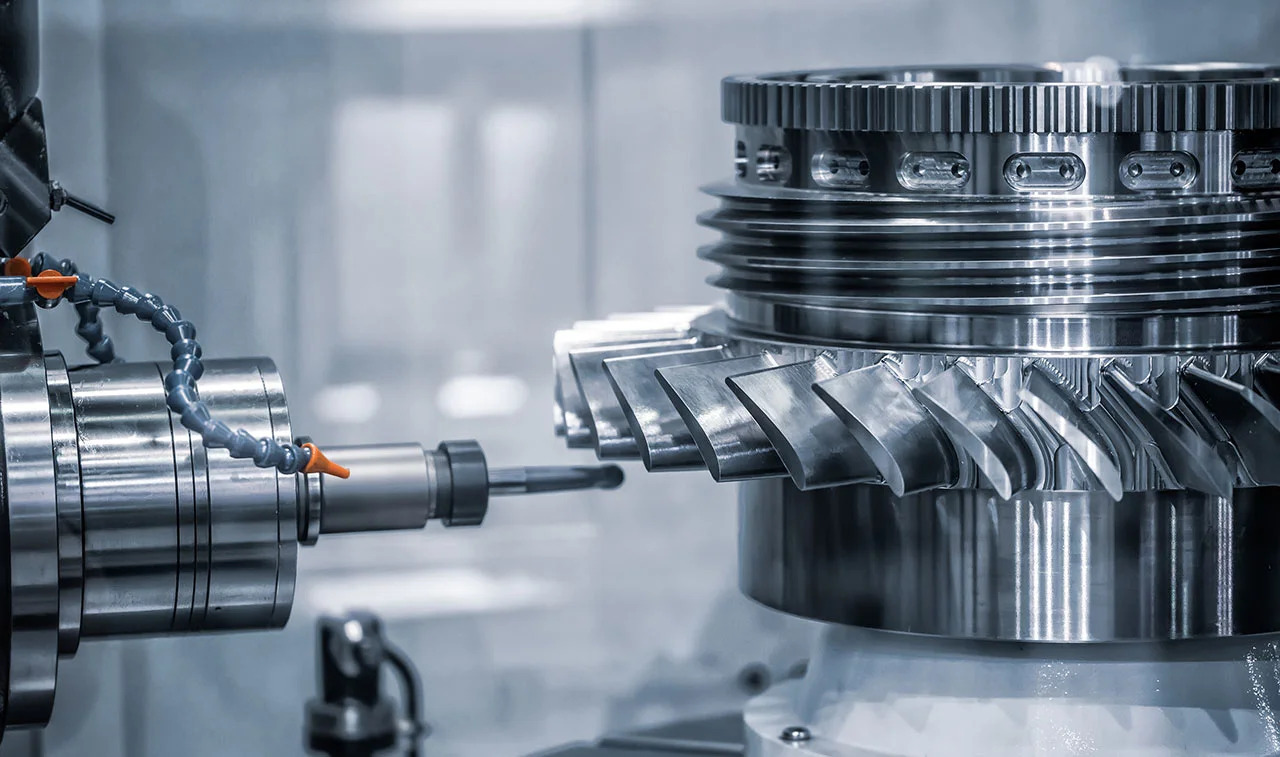

7 Reasons Why 3D Printing is the Future of Aerospace Components Machining

The aerospace industry is changing fast, thanks to 3D printer technology for aerospace. This modern method of making parts is improving how designs are created and built. It’s more flexible, faster, and cost-efficient. With its many advantages, 3D printing is shaping the future of aerospace like never before.

1. Design Freedom Like Never Before

Traditional methods of making aerospace parts are often limited by tools and processes. However, 3D printing allows engineers to create designs that were once impossible. Complex shapes, lightweight structures, and intricate details can now be achieved effortlessly. This freedom ensures that parts are not only functional but also optimized for weight reduction and strength, which are critical for aerospace applications.

2. Reduction in Manufacturing Time

Aerospace projects often take years to complete due to the time required for machining and assembly. With 3D printing, components can be produced in a fraction of that time. This speed doesn’t just save time—it accelerates innovation, allowing manufacturers to test and refine their designs quickly. As a result, aerospace companies can respond faster to new challenges and opportunities.

3. Cost-Effective Production

Creating aerospace parts through traditional methods can be expensive due to material waste and labor costs. 3D printing minimizes waste by using only the material needed for the part. Additionally, it reduces the reliance on extensive tooling, which significantly cuts expenses. For industries like aerospace, where precision and quality are non-negotiable, this cost-efficiency is a game-changer.

4. Improved Material Utilization

3D printer technology for aerospace allows the use of high-performance materials like titanium, aluminum, and advanced composites. These materials are essential for building durable and lightweight components. With 3D printing, materials can be layered with extreme accuracy, ensuring that each part meets the highest standards of performance and safety.

5. Sustainability in Manufacturing

Environmental concerns are becoming a priority in every industry, including aerospace. Traditional manufacturing often leads to significant material waste and energy consumption. In contrast, 3D printing promotes sustainability by reducing waste and utilizing energy-efficient processes. This aligns perfectly with the aerospace sector’s goal of building greener technologies.

6. Easier Customization

Each aerospace project has unique requirements, making customization an essential factor. 3D printing allows manufacturers to tailor components to exact specifications without the need for expensive adjustments to equipment. This adaptability is crucial for meeting the specific needs of different aerospace applications.

7. Enhanced Prototyping Capabilities

Prototyping is vital for testing and refining aerospace designs. 3D printing streamlines this process by enabling the rapid creation of prototypes. Engineers can experiment with multiple iterations in a shorter timeframe, leading to better final products.

Final Note: The Future is Here

The rise of 3D printer technology for aerospace is transforming the industry. It’s fast, cost-effective, and sustainable. From quick prototyping to creating lightweight, complex parts, 3D printing is changing how aerospace components machining is done. This technology is paving the way for smarter, greener, and more efficient aerospace manufacturing.