How Simcenter Enhances Product Development Efficiency

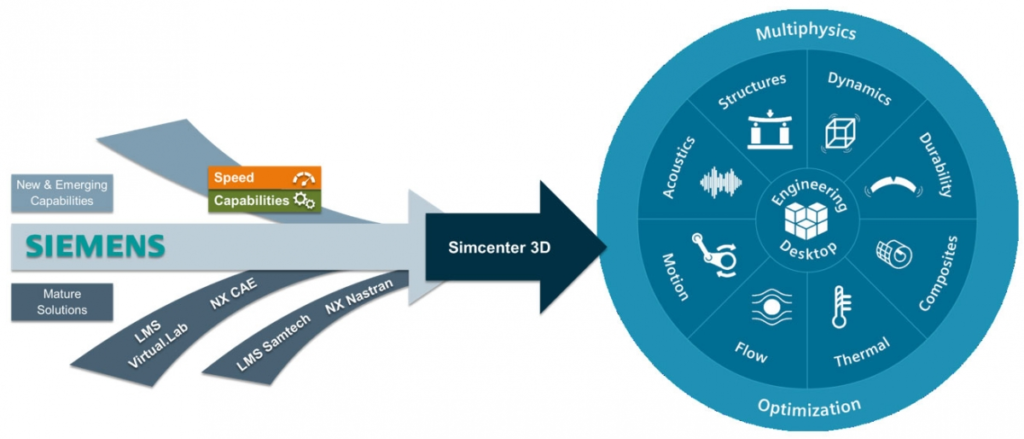

Simcenter is a powerful software tool that is helping companies improve their product development process. It provides simulation capabilities that allow engineers to test and refine their designs before building a physical prototype. This approach leads to faster development times, lower costs, and better final products. Simcenter combines several simulation techniques into one platform, allowing users to perform a variety of analyses in different areas, such as fluid dynamics, thermal performance, and structural analysis.

Companies in various industries rely on Simcenter for its ability to streamline the development process. Whether you are working on automotive, aerospace, or consumer products, Simcenter can help you refine your product designs and get them to market faster. In this blog, we’ll explore how Simcenter can enhance product development efficiency and why it is becoming a must-have tool for engineering teams around the world.

Note – Looking to enhance your product development process with Simcenter? Get in touch with our team at DDSPLM to explore how this powerful software can streamline your engineering workflow and deliver faster, more efficient results. Contact us today to learn more about integrating Simcenter into your projects and take your product development to the next level!

What Is Simcenter?

Simcenter is a software suite that combines simulation, testing, and predictive analytics. It allows engineers to simulate real-world conditions in a virtual environment, which helps them understand how a product will perform before building a physical prototype. The software integrates with other tools to provide a full range of testing options. It is flexible and can be used in different industries, making it one of the most versatile tools available for product development.

By using Simcenter, engineers can simulate how their products will perform under various conditions. This could include simulating the effects of wind on a car, the performance of materials under stress, or the efficiency of a cooling system. These simulations help to identify potential issues early in the design process, which reduces the need for costly physical prototypes. Simcenter’s ability to provide accurate simulations helps engineers make better decisions faster, speeding up the entire development process.

Key Benefits of Using Simcenter

One of the major benefits of Simcenter is its ability to reduce development time. Traditional product development often requires multiple rounds of physical testing, which can be time-consuming and expensive. With Simcenter, engineers can simulate different conditions and environments early in the design process, allowing them to identify potential issues and make adjustments before building physical prototypes. This leads to faster design cycles and a more efficient development process.

Another key benefit is cost reduction. Simcenter helps to minimize the need for physical testing, which can be expensive. By simulating different conditions, engineers can test their designs without the need for physical prototypes. This not only reduces material costs but also lowers labor costs. Simcenter’s simulation capabilities also help improve product quality by identifying and addressing potential issues before they become problems in the final product.

Simcenter also improves collaboration among team members. Engineers, designers, and other stakeholders can work together more effectively by using a shared platform that provides real-time insights into product performance. This collaboration helps to reduce misunderstandings and errors, leading to a smoother development process.

How Simcenter Improves Product Testing

Simcenter enhances product testing by allowing engineers to simulate real-world conditions. For example, if you are developing a new car, Simcenter can help you simulate how the vehicle will perform in different weather conditions, such as rain, snow, or extreme heat. It can also simulate the effects of wind and aerodynamics on the vehicle. This allows engineers to test the car’s performance before building a physical prototype.

In addition to automotive testing, Simcenter can be used in other industries, such as aerospace, energy, and electronics. For example, engineers can use Simcenter to test the thermal performance of an electronic device. This helps them determine how the device will dissipate heat and ensure that it will not overheat during use. By simulating these conditions early in the design process, engineers can make adjustments to improve performance and avoid costly design changes later.

Simcenter also enables engineers to test the structural integrity of products. Whether you are designing a building, a bridge, or a piece of machinery, Simcenter can simulate how the structure will respond to different forces, such as wind, earthquakes, or heavy loads. This helps to ensure that the structure will be strong and stable, reducing the risk of failure.

Simcenter and Predictive Engineering Analytics

Another important feature of Simcenter is its predictive engineering analytics capabilities. Predictive engineering analytics allows engineers to use data from past simulations and tests to predict future performance. This helps engineers make more informed decisions about product design, leading to better outcomes.

For example, if you are developing a new piece of machinery, you can use predictive analytics to simulate how the machine will perform over its entire lifecycle. This allows you to identify potential issues, such as wear and tear, before they occur. By predicting future performance, engineers can design products that are more reliable and have a longer lifespan.

Simcenter’s predictive engineering analytics also helps engineers optimize their designs. By analyzing data from past simulations, engineers can identify areas where performance can be improved. This helps to create more efficient products that meet customer needs more effectively.

How Simcenter Supports Collaboration in Product Development

Collaboration is a critical aspect of product development, and Simcenter enhances this by providing a platform that allows team members to work together more effectively. When developing a product, engineers, designers, and other stakeholders need to communicate and collaborate to ensure that the final product meets expectations. Simcenter allows team members to share simulations and analysis in real-time, which helps to reduce errors and misunderstandings.

Simcenter’s collaborative features are particularly beneficial for large projects that involve multiple teams or departments. For example, if you are working on a complex product, such as an aircraft or a vehicle, different teams may be responsible for different components. Simcenter allows these teams to share data and insights, ensuring that the various components of the product work together seamlessly.

By improving collaboration, Simcenter helps to speed up the development process and ensure that the final product meets the desired quality standards. This makes it a valuable tool for any company looking to improve their product development efficiency.

Conclusion

Simcenter is a powerful tool that can greatly enhance product development efficiency. By allowing engineers to simulate real-world conditions early in the design process, Simcenter helps to reduce development time, lower costs, and improve product quality. Its predictive engineering analytics capabilities also enable engineers to optimize their designs and predict future performance, ensuring that products are reliable and efficient.

Additionally, Simcenter supports collaboration among team members, allowing them to work together more effectively and reducing the risk of errors. Whether you are working on a small product or a large, complex project, Simcenter can help streamline the development process and improve outcomes.

In summary, Simcenter is a valuable tool for any company looking to improve their product development efficiency. Its ability to provide accurate simulations, predictive analytics, and collaboration features make it a must-have for engineering teams looking to stay competitive in today’s fast-paced market.

For more insightful articles related to this topic, feel free to visit todaybusinessposts.com